Product: HP Neutral Plus 50

Guardian Zoujaj International Float Glass Co, LLC

“Guardian RAK” P.O.Box : 6297, Al Jazirah Al Hamra, Ras Al Khaimah, UAE

+971 7 205 8000 Web Site www.guardianglass.com

Saudi Guardian International Float Glass Co.Ltd,

Al Jubail 31961, Kingdom of Saudi Arabia. Phone +966 13 3503777.

Website www.guardianglass.com.

GUARDIAN SELECT OPTICAL QUALITY SPECIFICATION

SECTION 08 8000 | GLAZING

PART 1 GENERAL:

1.1 SECTION INCLUDES

- 1. Glass products.

- 2. Laminated glass.

- 3. Insulating glass.

1.2 RELATED REQUIREMENTS

- 4. Section 057313 "Glazed Decorative Metal Railings" for glazing in railings.

- 5. Section 084126 "All-Glass Entrances and Storefronts."

- 6. Section 084233 "Revolving Door Entrances" for glass in revolving door entrances.

- 7. Section 088113 "Decorative Glass Glazing."

- 8. Section 088300 "Mirrors."

- 9. Section 088813 "Fire-Rated Glazing."

- 10. Section 088853 "Security Glazing."

1.3 REFERENCE STANDARDS

- A. 16 CFR 1201 - Safety Standard for Architectural Glazing Materials;

- B. ANSI Z97.1 - American National Standard for Safety Glazing Materials Used in Buildings, Safety Performance Specifications and Methods of Test; 2010.

- C. ASTM C1036 - Standard Specification for Flat Glass; 2011.

- D. ASTM C1048 - Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass; 2012.

- E. ASTM C1172 - Standard Specification for Laminated Architectural Flat Glass; 2014.

- F. EN 12150 – Standard Glass in building - Thermally toughened soda lime silicate

- G. EN 1863- Standard Glass in building - Heat strengthened soda lime silicate glass.

- H. EN 1096- Standard Glass in Building- Coated glass

- I. EN 572- Standard Glass in Building-Basic Soda lime silicate glass products.

- J. EN 1279-Standard Glass in Building – Insulating Glass Units

- K. ASTM E 2190 - Standard Specification for Insulating Glass Unit Performance and Evaluation.

- L. GANA (GM) - GANA Glazing Manual; 2009.

- M. IGMA TM-3000 - North American Glazing Guidelines for Sealed Insulating Glass Units for Commercial & Residential Use; 1990 (2004).

- N. NFRC 100 - Procedure for Determining Fenestration Product U-factors; 2014.

1.4 SUBMITTALS

- A. Comply with Section 01 3000 - Submittal procedures.

- B. Product Data: Submit manufacture’s product data, including performance characteristics and installation instructions.

- C. Shop Drawings: Submit manufacturer’s or Fabricator’s shop drawings, including plans, elevations, sections, and details, indicating glass dimensions, tolerances, types, thickness, and coatings.

- D. Samples: Submit manufacturer’s samples of each type, thickness, and coatings

- F. Fabricator’s Certification: Submit fabricator’s certification by manufacturer.

- G.Warranty: Submit manufacturer standard warranty for sealed insulating glass units.

1.5 QUALITY ASSURANCE

- A. Manufacturer Qualifications: Company specializing in manufacturing the products specified in this section with minimum three years of documented experience.

- B. Installer Qualifications: Company specializing in performing work of the type specified and with at least three years documented experience.

- C. Manufacturer Qualifications for Insulating Glass Units with Sputter-Coated, Low-E Coatings: A qualified commercial insulating glass fabricator who is certified by coated glass manufacturer.

1.6 MOCK-UPS

- A. Comply with 01450 - Quality Control

- B. Provide mock-up of items as indicated including glass and air barrier and vapor retarder seal.

- C. Provide on-site glazing mock-up with the specified glazing components.

- D. Obtain acceptance of mock-ups by Architect before proceeding with work.

1.7 WARRANTY

- Visit https://www.guardianglass.com/me/en/warranty-information

PART 2 PRODUCTS:

2.1 MANUFACTURERS

- A. Guardian Zoujaj International Float Glass Co LLC, Al Hamrah Al Jazeerah, Ras Al Khaimah, United Arab Emirates. Phone +971 7 205 8000. Website www.guardianglass.com

- B. Saudi Guardian International Float Glass Co.Ltd, Al Jubail 31961,Kingdom of Saudi Arabia. Phone +966 13 3503777. Website www.guardianglass.com.

- C. Mirrored Glass Manufacturers:

- Saudi Guardian International Float Glass Co.Ltd, Al Jubail 31961,Kingdom of Saudi Arabia.

- Phone +966 13 3503777. Website www.guardianglass.com, https://www.guardianglass.com/me/en: Guardian Ultramirror®

2.2 APPROVED FABRICATORS

A. Provide products of one of the following Independent Select Fabricators, certified by Guardian to Elite Optical Quality Standard specified in this Section:

- Future Architectural Glass LLC, UAE.

- Gulf Glass Industries, UAE.

- Technical Glass and Aluminium Co LLC, UAE.

- Uniglass, Saudi Arabia.

- IKK, Saudi Arabia.

2.3 GLASS PRODUCTS

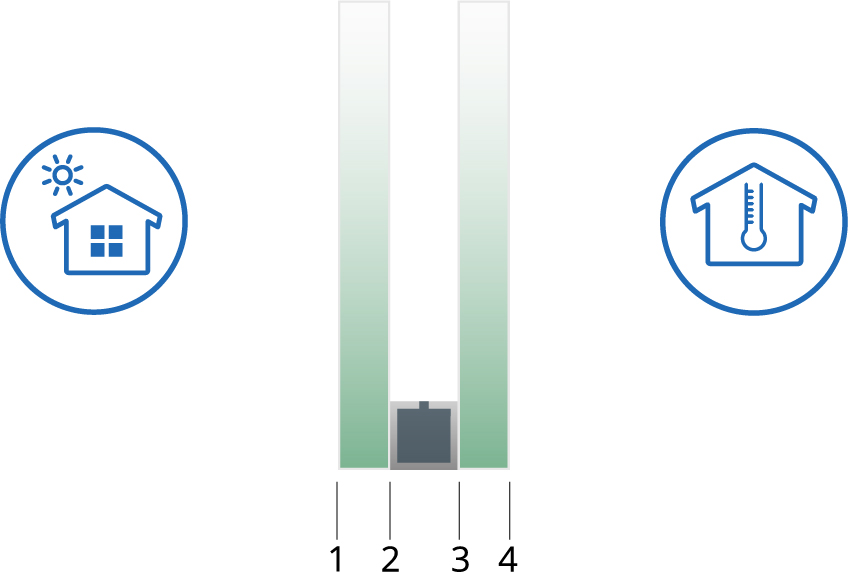

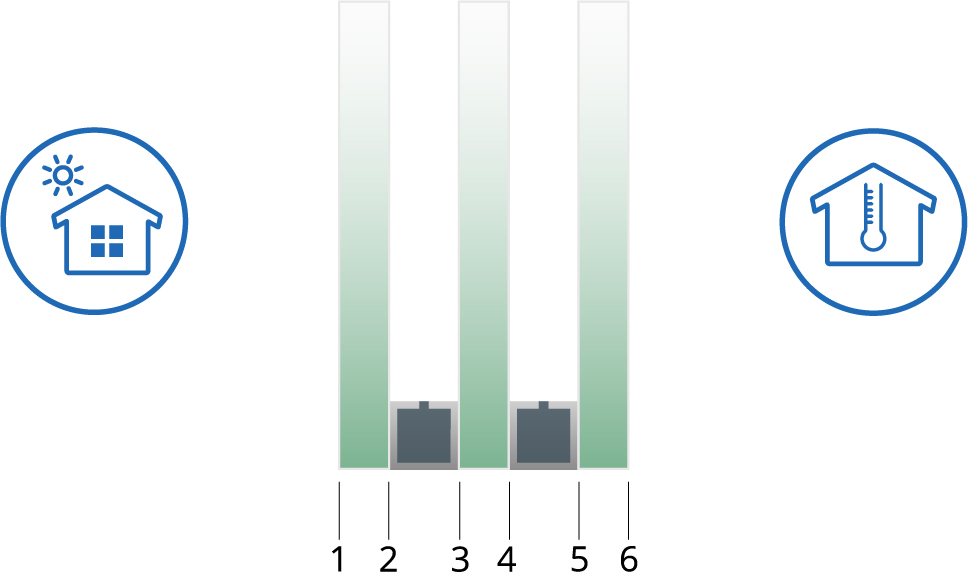

A. 1. Double Glazed Sputter-Coated Insulating Glass Units:

Conformance: ASTM E 2190 Standard Specification for Insulating Glass Unit Performance and Evaluation.[SS2]

Outboard Lite: Sputter-coated clear float glass.

- a. Annealed Clear Float Float Glass: ASTM C 1036, JIS R 3202 and EN 572 Type 1, Class 1, Quality q3.

- b. Glass Thickness: 6mm

- c. Vacuum Deposition Sputtered Coating: EN 1096, ASTM C 1376

- d. Coating on Surface No. 2: HP Neutral Plus 50

- e. Heat Treatment: [None] [Heat-strengthened, ASTM C 1048, Kind HS and EN 1863] [Tempered; ASTM C 1048, Kind FT; and EN 12150] as necessary to meet applicable codes and performance requirements.

2. Air Space: 12mm wide, hermetically sealed, dehydrated air space.

4. Inboard Lite: Clear Float

- a. Annealed Clear Float Float Glass: ASTM C 1036, JIS R 3202 and EN 572 Type 1, Class 1, Quality q3.

- b. Glass Thickness: 6mm

- c. Vacuum Deposition Sputtered Coating: EN 1096, ASTM C 1376

- d. Coating on Surface No. 4: No coating

- e. Heat Treatment: [None] [Heat-strengthened, ASTM C 1048, Kind HS and EN 1863] [Tempered; ASTM C 1048, Kind FT; and EN 12150] as necessary to meet applicable codes and performance requirements.

Specifier Notes: Specify the method of heat treatment. Guardian recommends heat-strengthened where necessary for thermal stress management or other reasons, unless fully tempered glass is specifically required.

5. Glass Unit Performance Characteristics:

- a. 48 % Visible Light Transmittance

- b. 26 % Visible Light Reflectance Outdoors

- c. 20 % Visible Light Reflectance Indoors

- d. 27 % Direct Solar Energy Transmittance

- e. 35 % Direct Solar Energy Reflectance Outdoors

- f. 1.625 W/m²·K Summer U-Value Daytime

- g. 0.32 Solar Heat Gain Coefficient:

- h. 0.37 Shading Coefficient

- i. 0.32 Relative Heat Gain

- j. 94.2 General Color Rendering Index

Optical Distortion Limits:

- j. Maximum peak-to-valley roll wave 0.003 inch (0.08 mm) in the central area of the glass lite, and 0.008 inch (0.20 mm) within 12 inches (305 mm) of the leading and trailing edge of the lite, per measured in accordance with ASTM C 1651, or EN12150 and EN 1863.

- k. Maximum center-kink of 0.001 inch (0.025 mm) when roll wave is measured over the surface of the glass perpendicular to the direction of travel through the tempering furnace.

- l. Maximum localized and overall bow (warp) per lite shall be 0.031 inch (0.79 mm) per 305mm: one-half of maximum allowed by ASTM C 1048, or EN 12150 and EN 1863.

- m. Measure glass lites for optical distortion using Osprey® (version 7 or higher, by Lite Sentry) on-line distortion measurement system (or manufacturer approved equivalent). Retain test reports for three years following substantial completion. Submit test reports upon Architect's request.

B. Laminated Glass: Float glass laminated in accordance with ASTM C1172.

- Laminated Safety Glass: Complies with ANSI Z97.1 and 16 CFR 1201 test requirements for Category II.

2.4 INSULATING GLASS UNITS

A. Insulating Glass Units: Factory-assembled units consisting of sealed lites of glass separated by a dehydrated interspace, qualified according to ASTM E 2190. Provide insulating glass units free of skips or voids in the primary or secondary seals. Utilize an automated vertical insulating line for insulating glass unit assembly, sealing, and curing processes.

- Sealing System: Dual seal, with polyisobutylene primary and silicone secondary sealants.

a. Secondary sealants approved by coated glass manufacturer.

- Metallic Spacer: [Manufacturer's standard spacer material and construction] [Aluminum with clear anodic finish] [Thermally broken aluminum] [Stainless steel], with desiccant consisting of molecular sieve or silica gel, or a blend of both.

- Non-Metallic Warm Edge Spacer: Low-conductivity, high wind load-resistant structural silicone spacer, with integrally incorporated desiccant and narrow sightline profile. Please add appropriate information below:

Spacer width: ............................

Spacer Height: ............................

Spacer Manufacturer: ............................

B. Edge Deletion: Delete low-E coating at perimeter of coated lite prior to fabrication of insulating glass units according to coated glass manufacturer’s instructions.

2.5 SOURCE QUALITY CONTROL

- A. Sealant Uniformity: Perform IGMA Sealant Uniformity of Mix Test not less than once per shift. Submit test reports upon Architect's request.

- B. Residual Moisture Content: Perform IGMA Residual Moisture Content by Head of Absorption Test. Perform test in accordance with desiccant manufacturer’s written recommendations. Submit test reports upon Architect's request.

- C. Anisotropy (Iridescence): Perform anisotropy (iridescence) scan utilizing detection system approved by glass manufacturer. Perform test in accordance with detection system manufacturer’s written instructions. Continuously monitor production and record results. Maintain results for a period of not less than 10 years.

- D. Color Variation of Glass Coatings: Provide vacuum deposition coatings on glass complying with color variation limits specified in EN 1096. Perform color monitoring utilizing spectrophotometer equipment approved by glass manufacturer. Perform test in accordance with manufacturer’s approved procedure. Test finished insulated glass units in accordance with reflected color specifications and in comparison, to approved mockup control sample. Statistically monitor production and record results. Maintain results for a period of not less than 10 years.